DragX is a surface treatment system for use in pipelines that creates a water- and oil-repellant, low-friction surface.

Created in partnership with

Development of DragX was supported by the U.S. Department of Energy (DOE), U.S. National Energy Technology Laboratory (NETL), and the U.S. Environmental Protection Agency (EPA).

01

Traditional pipeline coatings didn’t hold up

Factory-applied, flow-efficiency coatings for pipelines increase efficiency, mitigate corrosion and adhesion of debris, and reduce the cost of maintenance. But there’s room for improvement. Ttaditional coatings have had issues with pot life after preparation, extremely long curing times, and required coating-thickness which impacts business and capacity. These properties have made the adoption of in-situ-applied epoxy coatings impractical for many pipelines.

02

DragX is a nanocomposite that’s flexible, effective, and reduces cost

DragX is a novel surface treatment system for use in a variety of pipelines. DragX utilizes nanocomposite technology to create a water and oil-repellant, low-friction surface — even on corroded, in-service pipelines. The surface treatment is applicable on long, in-situ pipelines and is scalable to any pipe diameter. DragX is effective at a fraction of the thickness of conventional pipeline epoxy coatings, while imparting drag reduction, preventing corrosion, and reducing adhesion and the deposit of debris and impurities.

03

Why it matters

DragX has strong adhesion, abrasion-resistance, no adverse effects on purity of the fluids being transported, and increases flow capacities at decreased pressure, even for de-rated pipelines.

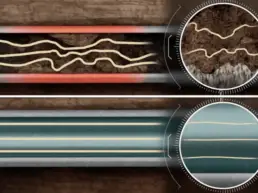

See how DragX works

Pipelines offer suffer from corrosion or deposition of debris, which creates drag. As a result, pipelines often need drag-reducing agents or maintenance.