HydroPel prevents hydrogen embrittlement, which makes natural gas pipelines safe for hydrogen transportation.

In partnership with...

HyroPel is one of several technologies that Oceanit is developing under EDGE (Energy Decarbonization for the Global Environment) to support the global energy transformation and make hydrogen into a viable clean-burning fuel source for a greener future.

HydroPel is currently deployed with our partners, Hawaii Gas, as we work to address the technical barriers in blending higher percentages of hydrogen into natural gas pipelines.

01

Hydrogen poses storage and transportation challenges

Hydrogen (H2) is one of the simplest and most abundant elements on earth and is widely considered a potential solution to the world’s energy appetite and decarbonization needs.

A critical issue in H2 storage and transport is hydrogen embrittlement, a process in which hydrogen’s relatively small molecules diffuse into the metal of the pipe or container they are in, making the metal brittle, which could lead to fracturing and failure. H2 is easily ignitable when in the presence of an oxidizer, so it’s critical to prevent hydrogen embrittlement in storage and transport.

02

HydroPel can be applied to existing pipelines

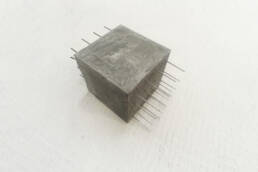

HydroPel is a nanocomposite surface treatment that can be applied to the interior walls of existing natural gas pipelines to make them safe for hydrogen transportation. It works by creating a passivating barrier through which H2 molecules are unable to penetrate. HydroPel can be applied in-situ to the walls of existing pipelines, forming this protective barrier between the gas and the metal that is at risk of embrittlement and fracturing.

03

Why it matters

This advanced nanocomposite eliminates the costs associated with manufacturing and installation of new, hydrogen-specific pipelines by enabling the use of already-existing pipeline networks. Additionally, HydroPel creates an ultra-slick, omniphobic surface that provides drag reduction to further decrease expenses by effectively lowering the energy needed to compress and move gas.

HydroPel enables clean-burning hydrogen distribution at scale.