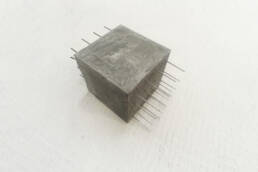

PiggyBack is an AI pipeline inspection tool that uses a standard cleaning PIG for virtual assessment.

01

Physical pipeline inspection is time-consuming

For the energy sector, pipeline transportation and inspection is critical to ensure safe and efficient transport, predict and prevent accidents, and meet environmental regulatory goals. “Pigging” is the practice of using PIGs, or Pipeline Inspection Gauges, which run through a pipeline and perform various maintenance, cleaning, and inspection operations.

02

PiggyBack makes it much more efficient

Oceanit’s PiggyBack takes pipeline inspection and maintenance to the next level, delivering deeper insights faster and in more detail. Including advanced features like multi-spectral imaging, on-board INS for precise geolocation data, and predictive AI for actionable insights, PiggyBack can pinpoint issues such as corrosion or erosion, debris or wax build-up, and pipe integrity defects.

PiggyBack data is analyzed with computer vision AI RIVEAL to process hundreds of miles of pipeline data in just minutes. The system helps to identify surface anomalies such as corrosion, flagging trouble areas and allowing operators to quickly determine courses of action.

03

Why it matters

PiggyBack can rapidly cover hundreds of miles of pipeline, providing actionable data to reduce maintenance costs, prevent accidents, and ensure ongoing safe and reliable operation. It also improved the quality of preparation and application of advanced surface treatments, such as Oceanit’s DragX or HydroPel nanocomposites.

“The big disruption with PiggyBack is that now you can do digital inspections and have your human inspectors focus on problematic areas. It really helped operators avoid unnecessary excavations.”

See how PiggyBack works in tandem with RIVEAL to conduct more efficient pipeline inspections.